Thermal Expansion Valve is referred to as TXV. The TXV is made to keep the evaporator as full of saturated refrigerant as possible while guarding against slugging or overheating of the compressor.

This, in turn, maintains the saturation temperature at the current evaporating pressure. The purpose of the thermal expansion valve is to regulate the amount of refrigerant that enters the evaporator in response to the cooling load. In order to try and maintain a constant superheat, TXVs also measure the superheat at the outlet and adjust the amount of refrigerant flowing into the evaporator accordingly.

For more information, keep reading.

Theory Of Operation

The cycle that enables air conditioning, or air cooling, depends on a thermal expansion valve. Four main components make up a basic refrigeration cycle: a compressor, a condenser, a metering device and an evaporator. In a circuit made up of these four components, air conditioning happens as a refrigerant moves through it. When refrigerant enters the compressor as a low-pressure, moderate-temperature gaseous substance, the cycle begins. The compressor pushes the refrigerant into a gaseous state at high pressure and temperature. The high-pressure, high-temperature gas next enters the condenser. By transferring heat to a medium with a lower temperature—typically ambient air—the condenser cools the high-pressure and high-temperature gas, enabling it to condense into a high-pressure liquid.

The expansion valve limits the flow of refrigerant entering the evaporator, lowering pressure and permitting isenthalpic expansion back into the vapor phase to happen at a lower temperature, producing a cooling effect from the higher pressure liquid. An expansion device of the TXV type has a sensing bulb filled with a liquid that is similar to the refrigerant in terms of thermodynamics. This bulb is thermally connected to the evaporator’s output so that the temperature of the refrigerant exiting the evaporator can be measured. The gas pressure in the sensing bulb provides the force to open the TXV, dynamically adjusting the refrigerant flow inside the evaporator and, as a result, the superheat acquired by the refrigerant that exits the evaporator.

The vapor’s excess temperature above its boiling point at the evaporating pressure is known as superheat. If there is no superheat, the refrigerant may not be completely vaporized in the evaporator and may instead be returned to the compressor as liquid. On the other hand, excessive superheat means that there isn’t enough refrigerant flowing through the evaporator coil, which means that a lot of it doesn’t have any liquid refrigerant to evaporate and isn’t providing much cooling there. The evaporator’s heat transfer will therefore be close to optimal by controlling the superheat to a low value, typically only a few degrees Celsius, without causing too much saturated refrigerant to be returned to the compressor.

Some thermal expansion valves are also specifically made to guarantee that a specific minimum flow of refrigerant can always pass through the system, and other types of thermal expansion valves can be made to regulate the evaporator’s pressure so that it never rises above a certain level.

Superheat & Pressure

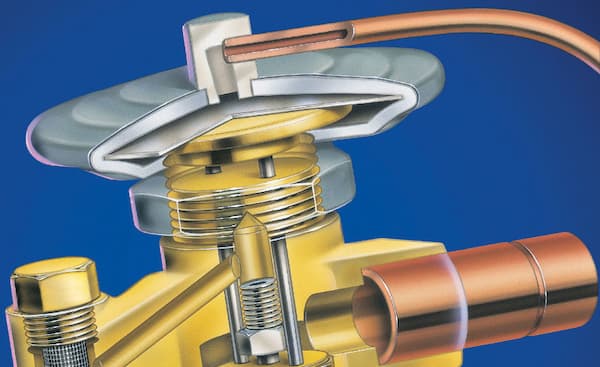

- The refrigerant inside the bulb boils due to the superheat, and the pressure that results from the boiling process. The pressure then passes through the hollow capillary tube and into the power head, which regulates the refrigerant flow.

- Inside the inlet of the expansion valve is a removable cartridge. This has an orifice that controls the refrigerant along with the valve. Depending on the required cooling capacity and the type of refrigerant, different size cartridges are available.

- The condenser supplies the refrigerant, which enters the valve body through the inlet. It comes in as a saturated liquid at high pressure and moderate temperature. A low-pressure, low-temperature vapor/liquid mixture is created as it travels through the valve body and leaves the valve through the outlet. As the pin is connected to the control head’s diaphragm, this affects the pressure-temperature phase and regulates the refrigerant flow.

How Does The Diaphragm Function?

- A thin metal sheet called the diaphragm oscillates up and down with the pin. A spring that can be altered to control the superheat is located beneath the diaphragm. The sensing bulb is located at the evaporator’s outlet. As a result, the evaporator’s cooling load rises and superheat builds up at the outlet. The evaporator outlet pipe and the sensing bulb are in direct contact, which allows thermal energy to transfer and cause the refrigerant inside the sensing bulb to expand and boil.

- The internal pressure rises as the refrigerant expands and boils. The capillary tube allows this rising pressure to pass through and enter the chamber above the diaphragm. After that, the pin is pushed downward as the pressure on the diaphragm rises. A pin inside the valve regulates how much refrigerant flows through an orifice assembly. The valve opens as a result of the pin being depressed against the stop. The refrigerant flow is increased when the stopper is depressed. The superheat at the outlet rises as the cooling load on the evaporator rises.

- When the sensing bulb at the outlet notices this, the refrigerant inside boils, increasing the pressure along the capillary tube. With the valve now open, more refrigerant can flow as a result of the pressure pushing the diaphragm down and the pin down. There is less pressure pushing the diaphragm down as more refrigerant flows because the superheat decreases and the pressure in the capillary tube and sensing bulb also decreases. As the pin moves up as a result of the spring pushing the diaphragm back up, the spring-loaded stopper starts to close the orifice, reducing the amount of refrigerant that can flow.

Typical TXV

Most of the time, it should be fine because the typical TXV is factory-set for 8 to 12 degrees of evaporator superheat. How should the evaporator superheat setting be adjusted? However, we should be more concerned with the compressor or total superheat. It is true that lower superheat will increase evaporator efficiency. We should typically have at least 20 degrees of total superheat when measuring the superheat on the suction line 6 from the compressor. By doing this, you can be sure that even in the presence of frost, the compressor won’t slug with liquid. To make sure that the compressor is properly cooled, the suction line temperature at the compressor shouldn’t go above 65 degrees. The discharge line temperature, measured six inches from the compressor, is the last but most significant reading. Higher discharge temperatures will cause compressor failures, so this temperature should never rise above 220 degrees. Lowering superheat will result in cooler compressor suction and discharge lines.

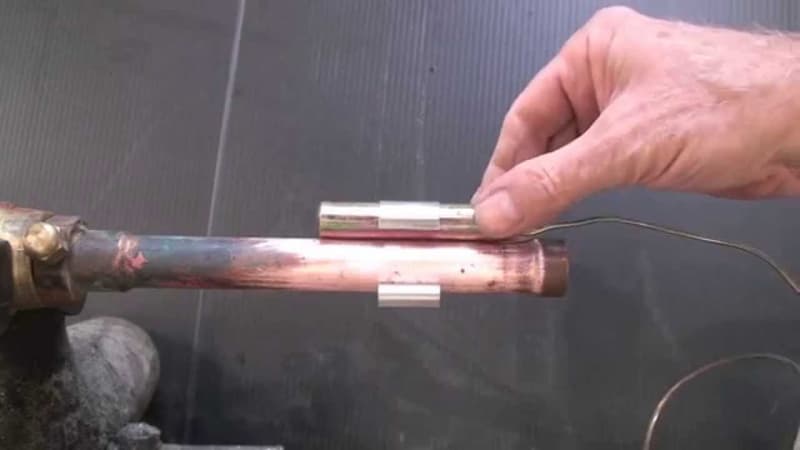

Since it functions as a modulating valve, the TXV cannot be opened or closed. Increased spring pressure and a higher superheat are the only effects of turning the adjustment stem clockwise. Reduced spring pressure will result in less superheat when the adjustment stem is rotated counterclockwise. The TXV may have lost its power head charge or may have become restricted when a functioning refrigeration system stops working, but it’s unlikely that it went out of adjustment. Don’t try to readjust the broken valve; instead, clean it or replace it. To avoid damaging the new valve when replacing a TXV by overheating it while brazing. For smaller suction lines, 5/8″ or less, the sensing bulb should be mounted tightly to the suction line on the evaporator outlet at the 9:00 or 3:00 position. The bulb should be mounted at the 4:00 or 8:00 position for suction lines 7/8″ and larger. A new system may require adjustments when it first starts up, especially if there are long line runs. See more about What Is A Runaway Truck Ramp?

TXV Types

The two primary categories of thermal expansion valves are: internally or externally equalized. The way the evaporator pressure affects the position of the needle varies between externally and internally equalized valves. In internally equalized valves, the evaporator pressure against the diaphragm is the pressure at the inlet of the evaporator (typically via an internal connection to the outlet of the valve), whereas in externally equalized valves, the evaporator pressure against the diaphragm is the pressure at the outlet of the evaporator. Thermostatic expansion valves with external equalization make up for any pressure loss through the evaporator A pressure drop in the evaporator will result in an increase in superheat for valves with internal equalization.

Single circuit evaporator coils with low pressure drops can use internally equalized valves. An externally equalized valve must be used if a refrigerant distributor—rather than a valve on each evaporator—is used for multiple parallel evaporators. All applications are compatible with externally equalized TXVs, but an internally equalized TXV cannot take the place of an externally equalized TXV. A type of externally equalized thermal expansion valve known as the block type valve is frequently used in automotive applications. In this type, either a sensing bulb is positioned within the suction line connection within the valve body and is in constant contact with the refrigerant that flows out of the evaporator’s outlet, or a heat transfer means is provided so that the refrigerant is able to exchange heat with the sensing charge contained in a chamber located above the diaphragm as it flows to the suction line.

The majority of systems that regulate refrigerant superheat use bulb/diaphragm types, but larger systems or systems with multiple evaporators are increasingly using electronic expansion valves to enable independent adjustment of the evaporators. Electronic valves can offer greater control flexibility and range than bulb/diaphragm types, but they also increase system complexity and point of failure because they need additional temperature and pressure sensors, as well as an electronic control circuit. For the majority of electronic valves, a needle valve is operated by a stepper motor that is magnetically driven through the sealed valve body by stator coils on the outside of the device. This stepper motor is hermetically sealed inside the valve. See more about What Is A Straight Truck?

The Bottom Line

The Thermal Expansion Valve (TXV) is a crucial piece of machinery used in the HVAC sector. The valve is used to control the amount of refrigerant released to the evaporator section. This regulates the difference between superheat and the actual refrigerant temperature at the evaporator outlet.

I appreciate you taking the time to read.